Welcome to Bosch Blue. This is the website of the professional blue power tools from Bosch – for trade and industry professionals. The Power Tools Division of the Bosch Group is the world market leader for power tools and power tool accessories. The core success factors are innovative strength and pace of innovation. Cordless tools with lithium-ion technology, e.g. Cordless screwdrivers, cordless angle grinders, cordless jigsaws or cordless rotary hammers, constitute an important part of our product range. In the stone and concrete working segment, we are a leading manufacturer of rotary hammers, drills, impact drills and core drills.

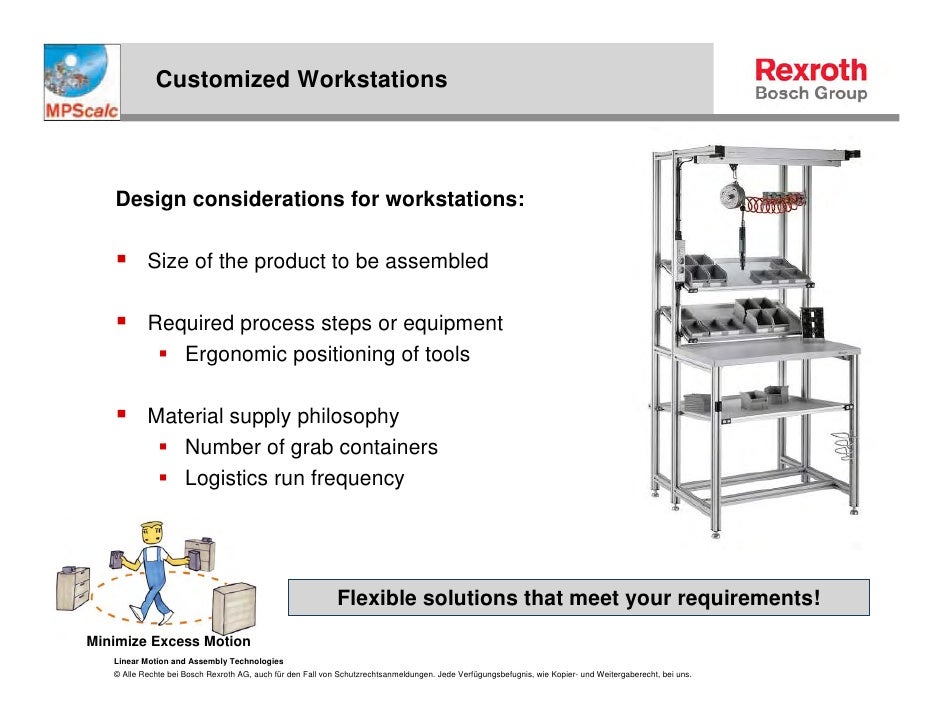

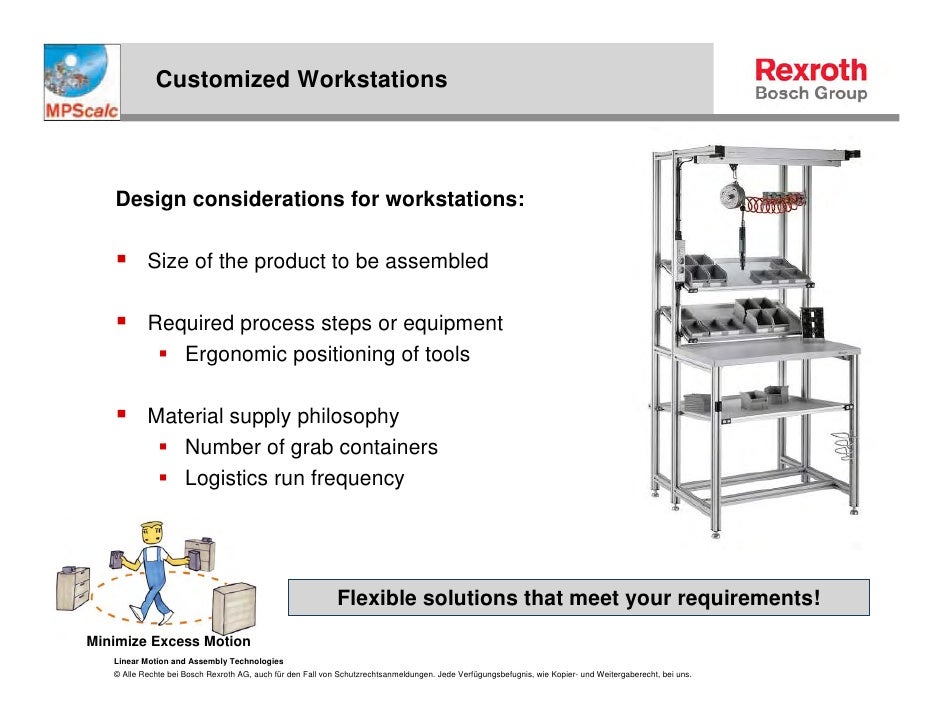

The main concern of modern production is to avoid waste. The MPS Manual Production Systems from Rexroth have been developed strictly in line with aspects for lean production, enabling simple and fast planning and implementation of lean production installations. Bosch Manual Assembly System A unique collaboration between Bosch Rexroth and Tulip The Smart Workstation is the result of a strategic alliance between Bosch Rexroth and Tulip.

By inventing SDS-plus and SDS-max, Bosch Power Tools has set market standards for toolholders in this segment. We offer pioneering table saws, jigsaws, hand-held circular saws and sabre saws for joiners and carpenters in the woodworking trade. The wood range is complemented by random orbit sanders, belt sanders, orbital sanders, planers and chainsaws. Our metalworking tools feature exceptionally high power and robustness – be it angle grinders or straight grinders. We offer matching system accessories for all blue power tools, including guide rails for routers and plunge saws and also appropriate dust extraction systems.

It's in your hands. Bosch Professional.

What is Lean? Simply stated, the core idea of lean manufacturing can be summed up as: ”relentlessly working on eliminating waste from the manufacturing process”.

Waste is defined as any activity that does not add value from the customer’s perspective. Minecraft avatar ba sing se map download free. According to research conducted by the Lean Enterprise Research Centre, 60% of production activities in a typical manufacturing operation are waste. They add no value at all for the customer. Most companies have a tremendous opportunity to improve operations using lean manufacturing principles and other manufacturing best practices. Principles and practices that enable you to deliver higher quality products at significantly lower costs. Download emulator ps2 windows 7 32 bit. Bosch Aluminum Structural Framing for Your Lean Solutions Lean manufacturing is made easy with our aluminum framing workstations, known as.

Based on our easy-to-reconfigure aluminum framing, you can configure your lean system exactly as you need it. It's robust enough to stand up to hundreds of changes - so you can meet your customers' changing demands without wasting your original investment. By designing your Lean work cell solutions with the Bosch modular system, you can easily achieve a systematic approach to identifying and eliminating waste through continuous improvement by flowing the product with the pull process of true Lean manufacturing perfection. Let Our Experts Help Pacific Integrated Handling has been helping our customers eliminate waste in their production activities and manufacturing facilities for many years and we can help you too. Whether you are just beginning to consider using lean principles or have a full blown lean initiative in place and need some help fine-tuning your waste reduction, we have the people, products and know-how to help you reach your lean goals.